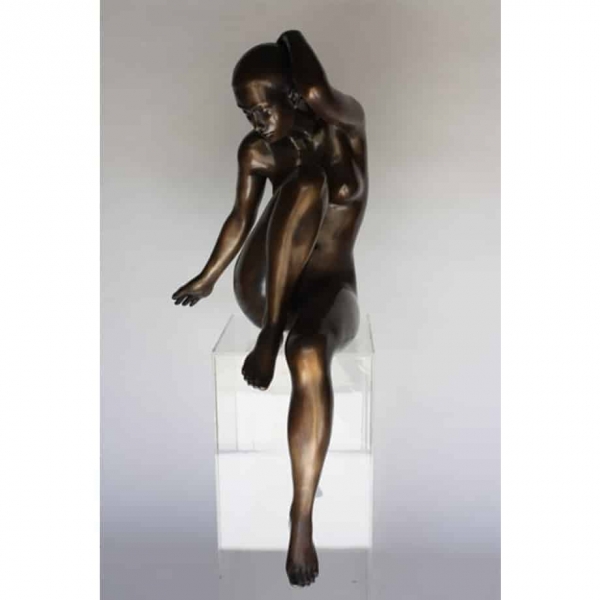

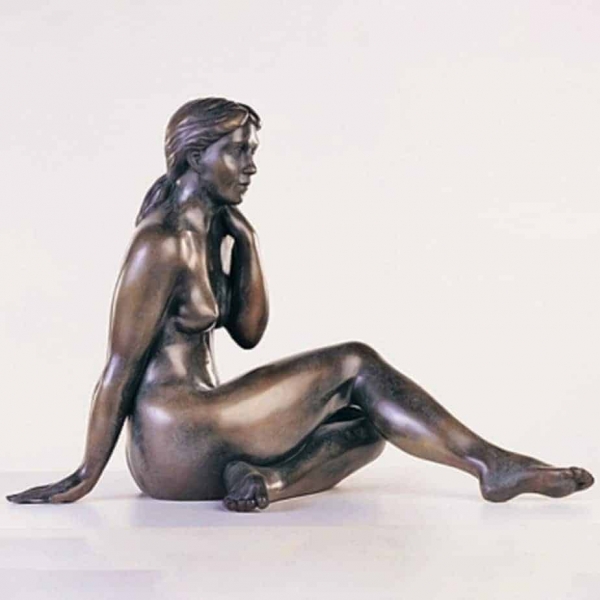

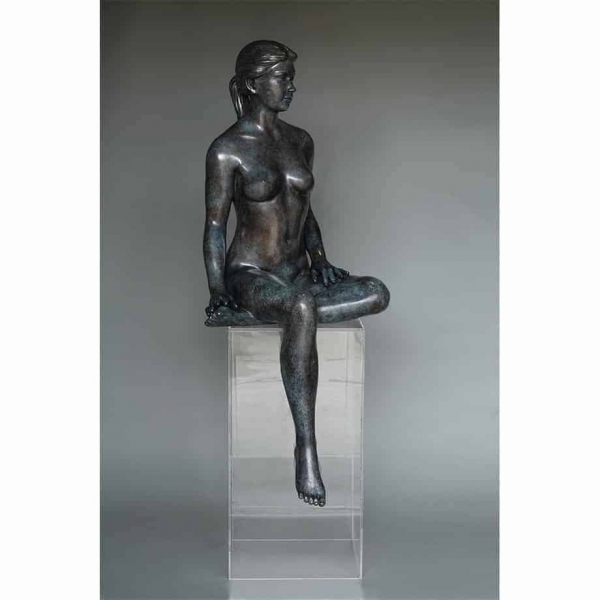

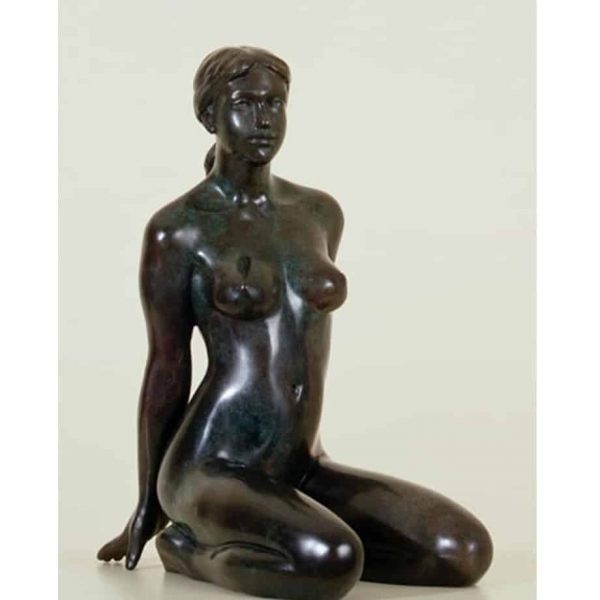

Figurative Bronze Sculpture

Our figurative bronze collection captures the eternal beauty of the human form with unparalleled artistry. These sculptures don't just represent figures, they embody the grace, strength, and emotional depth that make us human. Each piece invites contemplation, rewarding viewers with new discoveries each time they're encountered..

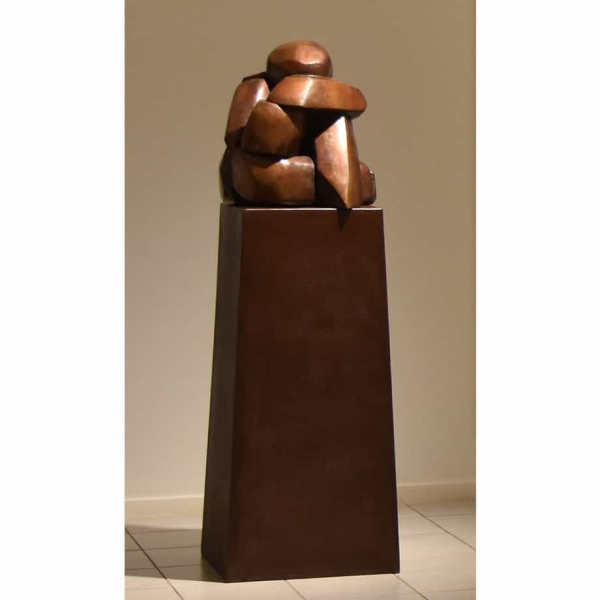

Abstract Bronze sculpture

View our collection of bronze Abstract sculpture, Creative Sculpture that desires to create conversation, test

the extent of a material or explore a theoretical concept in a physical space.

Custom Pieces & Sculpture Commissions.

All items on the website are available as they are, however, most of our sculptors are practising and are

willing to make adjustments to future editions or work with clients to design bespoke pieces.

Exceptional Quality Bronze

ARTpark Australia only represents and presents sculptural work of the highest quality and finish. All of our

Bronze Sculpture are forged and formed in Australia’s leading metal foundries. Bronze sculpture made to a

high standard with a quality patina will look the same to you as it will to your great grand children.

ARTpark also verifies all sculptural works with an authenticity certificate – Guaranteeing the edition

number and provenance of every sculptural artwork.

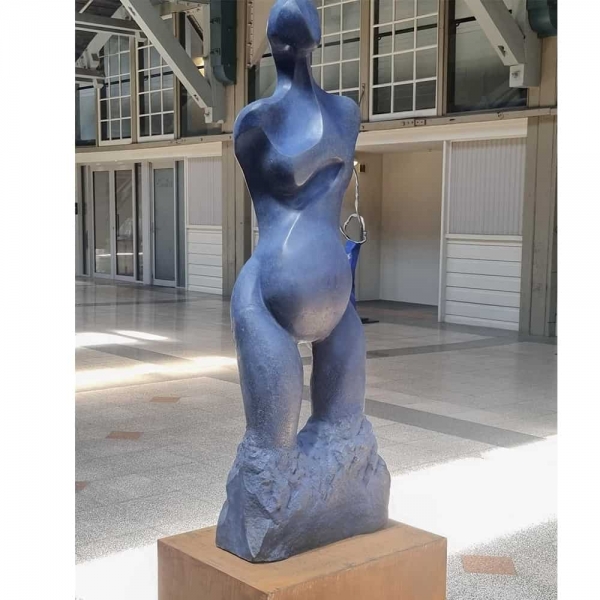

Popularity in the Art Market

Bronze is a popular choice for contemporary sculpture - Bronze has a very distinctive look that can add a

touch of elegance to any space. bronze is also very adaptable material that can be cast into almost any

form, making it very versatile for artists.

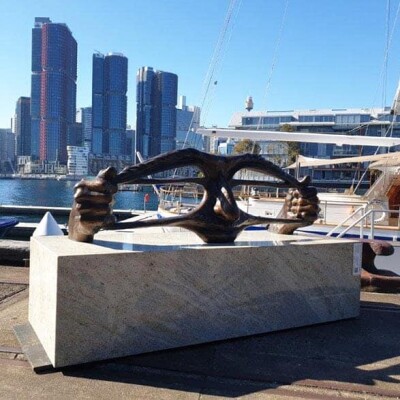

Many people see contemporary bronze sculptures as an investment and something that will appreciate in value

over time. There are many reasons why. First, bronze is an incredibly strong material that can withstand a

lot of wear and tear. With minimal maintenance a bronze sculpture will look as good the day it was

constructed as it will in many years to follow. This also makes it ideal for outdoor sculptures exposed to

the elements.

Browse our exceptional range of Contemporary bronze sculptures

The Bronze Casting Process

Most Bronze sculpture is made through a casting process. Using what is known as Lost Wax technique Beginning

with the sculptor creating their artwork through their preferred initial medium. Once the design is

complete, the sculptor fashions a mould of the work.

Molten wax is poured into this rigid mould and swirled around until an even coating is achieved, usually

about 3 mm thick, covers the inner surface of the mould. This is repeated until the desired thickness is

reached. This hollow wax copy of the original model is removed from the mould.

Each hollow wax copy is then "chased": a heated metal tool is used to rub out the marks that show where the

pieces of the mould came together. The wax is dressed to hide any imperfections. The wax now looks like the

finished sculptural piece.

The wax copy is dipped into a sand-like ceramic stucco. This shell is allowed to dry, and the process is

repeated until at least a half-inch coating covers the entire piece. The bigger the piece, the thicker the

shell needs to be. The core is also filled with fire-proof material.

The ceramic shell-coated piece is placed in a kiln, hardening the silica coatings into a shell, and the wax

melts and runs out Now all that remains of the original artwork is the negative space formerly occupied by

the wax, inside the hardened ceramic shell.

Metal is melted in a furnace, then poured carefully into the shell. The shell has to be hot also otherwise

the temperature difference would shatter it. The filled shells are then allowed to cool.

The shell is hammered or sand-blasted away, releasing the rough casting. Just as the wax copies were chased,

the casting is worked until the telltale signs of the casting process are removed, so that the casting now

looks like the original model. Pits left by air bubbles in the casting and the stubs of the spruing are

filed down and polished.

Finishing process can now by applied the sculpture. - Common choices are highly polished finish or a coloured

patina.

As you can imagine this is a highly technical process that takes years to perfect.

![moulin rouge-BRONZE-with--TEAL--PATINA[,Free-standing,bronze-outdoor]blazeski-australian-abstract-sculpture](https://artpark.com.au/wp-content/uploads/2014/12/Moulin-Rouge-175x29x29cm-HR4-600x600.jpg)

![RONZE-with--TEAL--PATINA[,Free-standing,bronze-outdoor]blazeski-australian-abstract-sculpture](https://artpark.com.au/wp-content/uploads/2017/10/Regeneration-of-the-Princess-Bronze-194x60x40-SQ-600x600.jpg)

![BRONZE-with--TEAL--PATINA[,Free-standing,bronze-outdoor]blazeski-australian-abstract-sculpture](https://artpark.com.au/wp-content/uploads/2022/09/Talk-to-Me-Bronze-170x120x60cm.1-600x600.jpg)

![Lissajous 70cm [stainless-steel]](https://artpark.com.au/wp-content/uploads/2022/07/BS-lissajous_70x65x30cm-400x400.jpg)

![Motion III - 250cm [Coated]](https://artpark.com.au/wp-content/uploads/2022/07/Motion-3-in-red-250cm-Bronze-TabletopBen-Storch-sculpture-australian-abstract-twisted-form-art-600x600.jpg)